(1) Food release paper: high temperature resistant, moisture-proof, oil proof, generally used in food industry packaging.

(2) Ordinary release paper: moisture proof, oil proof, play a product isolation role, applicable industries: electronics, car foam, printing, etc., its use range is mostly with sticky, especially adhesive tape, so release paper is generally used in products that need to use adhesive tape.

(3) PVC wallpaper, PVC leather coating foaming process to undertake the role. 5: Yellow single and double-sided coated release paper: the common base paper specifications are 70g, 75g, 110g, 120g, 140g. The base paper includes ordinary yellow paper, imported yellow paper, all wood pulp yellow paper, etc. It can be 1600mm on one side and coated with silicon on both sides

1270 mm wide. 6: White single and double-sided coated release paper: common base paper weight: 39G 45g 50g 60g 75g 75g 85g 95g 120g 140g 160g. The base paper materials include double adhesive base paper, whole pulp white paper, etc., with the conventional weight from 940mm-

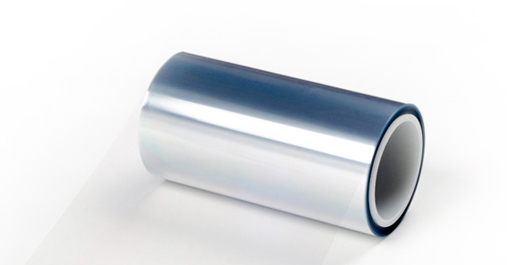

2040 mm, the narrowest can be divided into 22mm. Commonly used in the adhesive industry. It can produce single and double coated silicon. Anti stick paper, also known as silicon peel paper, has a three-layer structure: the first layer, paper base; the second layer, lamination; and the third layer, silicone oil. It can be used in electronic products, automotive foam, printing and so on. In most cases, it is used with viscous materials, especially adhesive tapes. [1] In wet prepreg production, release paper is placed on both the top and bottom of prepreg, and the lower release paper is attached to the prepreg with the winding up of prepreg, so the prepreg surface is usually protected by a layer of release paper.

Mobile site

Mobile site follow

follow