What is pet release membrane?

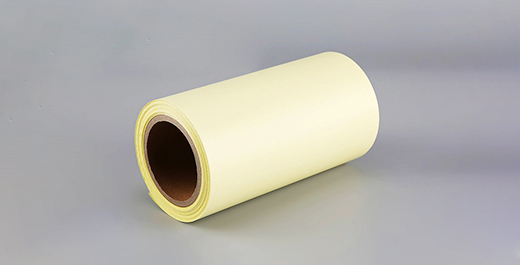

What is pet release membrane? Pet release film is a kind of material commonly used in heat transfer printing. The substrate is pet, which is coated with silicone oil, so it is also called silicone oil film. The conventional thickness ranges from 25um to 150um. It can be divided into cold and hot tearing and glossy surface. After anti-static and anti scratch treatment, the product has good adsorption and adhesion.

Pet release film, also known as pet silicone oil film, is to coat a layer of silicone oil on the surface of PET film to reduce the adhesion of PET film surface and achieve release effect. It can be divided into single-sided release film and double-sided release film. According to the release force, it can be divided into light release membrane, medium release membrane and heavy release membrane.

The commonly used thickness are: 0.012mm, 0.019mm, 0.025mm, 0.038mm, 0.05mm, 0.075mm, 0.1mm, 0.125mm, 0.188mm. The manufacturers of pet release film are equipped with large slitting and slicing machines, which can roll and slice according to your specifications.

Pet release film has been widely used in packaging, printing, silk screen printing, pad printing, signboard, membrane switch, flexible circuit, insulation products, circuit board, laser anti-counterfeiting, laminating, electronic, sealing material film, reflective material, waterproof material, medicine (plaster paper), sanitary paper, adhesive products, die cutting and stamping processing and other industries.

Pet release film is also known as heat transfer film, stripping film, isolation film, sliding film, Tianna paper, silicone oil film, anti mucous membrane, silicone oil release paper, silicone oil paper, mask film, pet release film, also known as pet transfer film. It is mainly used as the carrier of vacuum aluminizing, that is, the PET film is placed in the vacuum aluminizing machine and coated with glue and then compounded with paper. Then the PET film is stripped, and the aluminum molecular layer is transferred to the surface of paperboard through the adhesive effect, forming the so-called aluminized cardboard.

The production process of aluminum coated paperboard is: PET film → release layer → color layer → aluminum coating → coating layer → transfer to cardboard.

Mobile site

Mobile site follow

follow